“The longer Levin mowed, the oftener he felt the moments of unconsciousness in which it seemed not his hands that swung the scythe, but the scythe mowing of itself, a body full of life and consciousness of its own, and as though by magic, without thinking of it, the work turned out regular and well-finished of itself. These were the most blissful moments.” – Tolstoy, Anna Karenina.

I first discovered time disappearing in work when I tried my hand at bricklaying. I needed to make a low retaining wall that ran the length of the property, perhaps fifty metres in all, and at the time (first house) I didn’t have the cash to get someone else to do it, but I did have a large number of surplus bricks, so I decided to build it myself. It took me three Easters. Each Easter I’d work on a section, start in the morning after breakfast, mixing the mortar, getting into the rhythm of coating the brick, laying it down, lining it up with the string line, and then repeating. I’d not have been going long before I looked up and it was lunchtime. I’d have a break, come back, start again and before I knew it it was heading on for five, a new section of wall was in place, and the day had vanished.

Today was the first day in a long time on Project Hammer that I had felt this way. My last few posts have been largely frustrated, either being stuck on a particular problem, or just waiting for parts to arrive.

Did I mention why this bike is called Hammer? I don’t think so. I decided that my motorbikes needed names, and decided that I would name them primarily after musicians or bands who had been ‘big’ in the year the bike had been built. With this FZR being a 1990 the choice was straightforward, with MC Hammer’s ‘U can’t touch this’ being the single that has been remembered nearly thirty years later. And hence, Hammer.

It has been a rubbish few weeks. Between stressful work, dismal weather and the unexpected passing of my rescue dog (a former racing greyhound) to bone cancer, I desperately needed a lift today, and the Great Magnet provided me with one.

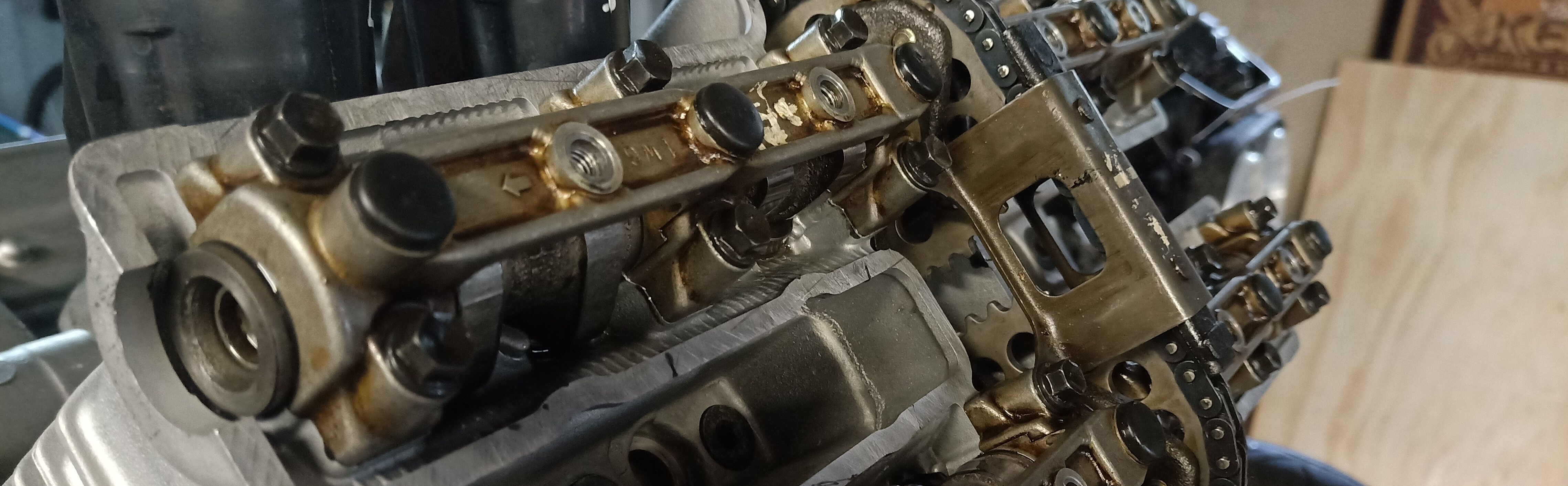

I started at 8am, blinked and it was suddely 10am (announced by the arrival of my lovely apprentice Julia, an orchestral violinist whose hands are worth more than my entire life, and who came over to risk it all helping me with a job that needed two pairs of hands to do), then it was lunchtime, and then all of a sudden it was 4pm and I had to tell myself that it was time to pull stumps. Unlike Tolstoy’s hero, mine wasn’t the rhythmic movement of the scythe through grass, but a whole heap of reassembly tasks, some of which were ones that I had been quite uncertain about. To sum up the achievements of the day, I managed to:

- Install the oil pump with the new gasket that arrived late on Friday

- Install the remaining crankcase bolt, the replacement for the one that oh-so-nearly caused disaster a while back

- Install the oil filter housing

- Install the block without breaking any piston rings

- Install the head without shearing any bolts or putting the gasket in wrong

- Install the oil line connecting the sump to the head

- Install all lifters in the right places thanks to my overly detailed labelling of which one went with which valve (with the help of a couple of egg cartons to keep them all separate and correct)

- Install the camshafts without breaking the shaft caps

- Install the cam chain guides and tensioner

- Install the starter motor

- Install the clutch basket, boss, friction plates, pushrods and pressure plate (including harvesting better springs from the old motor)

- Install the clutch cover, effectively finishing off the right hand side of the motor

- Install the water pipe running from the pump to the head

- Install the intake manifolds

The end result is a motor that is damned near ready to be installed. The biggest thing however was that it appears to all be lined up correctly – turning the motor with a socket attached to the end of the crankshaft proved that it moved freely, and with no valve-on-piston action that can be the case if the cams aren’t installed correctly.

The only very minor snag, which was completely expected, was finding that the valve clearances are miles out (almost all too tight) since the head was rebuilt, which means the cams need to come out again and some shims swapped over, but that wasn’t a job I was prepared to start at the end of a day – it can wait.

The lovely Julia asked me how long I thought it would be before Hammer would be back on the road, and for the first time I was able to make a decent estimate – perhaps another half-day of effort (plus a trip to Yamaha World to get the right thickness shims) to sort the valve clearances and get the valve cover back on and plugs in (which will, in essence, flag the end of the engine rebuild), perhaps another full day of effort to get the motor back in the frame connect it with the cooling and power systems along with carburettors, fuel tank and other bits to make it actually work, and then if (major if) it runs in that state then another half day to get the fairing back on – and that will be that.

Not out of the woods yet, but definitely a day that went by in the blink of an eye, and one where I made more progress than I’ve had in the last month.

This was indeed, to use the words of Tolstoy, a most blissful moment.